AUTONOMOUS CHLORIDE PRODUCTION (ACP)

The ACP units are used to disinfect water and preserve health. They are ideal to fight against epidemics in crisis or emergency situation.

ACP system is:

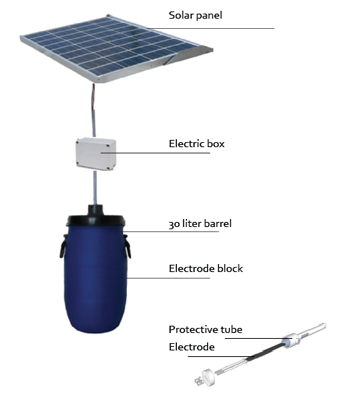

- The ACP is a mobile disinfectant production device that can be installed in a few hours to prevent or fight against the spread of waterborne diseases.

- It is energetically autonomous. The system includes a solar panel to produce sodium hypochlorite (chlorine) without using external power, often absent in crisis situations.

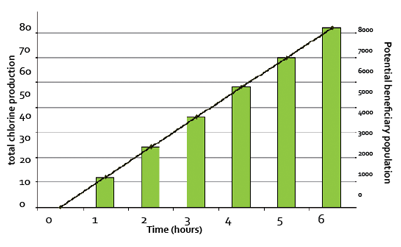

- This system can potentially provide drinking water to nearly 10,000 people on the basis of an average daily consumption of 20l / person, assuming the availability of logistics necessary to distribute doses.

- After production, it is sufficient to inject the chlorine in the water respecting the adequate chlorination rate (dose may vary depending on the waterquality).

EFFICIENCY OF ELECTROLYSIS

Example of a disinfectant production and treatment potential for a monopolar 4 plates electrode, two solar panels 95 Wc, a 3V voltage electrode, a 30 liters barrel and a salt concentration of25 g / l.

SAFETY

The quality of water is controlled using two parameters:

- Chlorination rate :

amount of chlorine injected per volume of raw water at the chlorinator to ensure adequate chlorination.

- Residual chlorine:

remaining amount of chlorine in the water at the time of distribution. This parameter is measured by colorimetry and must be associated to contact time, as it is universally used to determine if water is safe or not at a bacteriological point of view.

Polarity reversal of electrode

To ensure the sustainability of the chlorine production system, the APC units possess a button to invert the polarity of the electrodes. As an option this can also be done automatically. The electrode is thus self-cleaning, the totality of scaling that occurs during the reaction product settles to the bottom of the barrel.

To ensure the sustainability of the chlorine production system, the APC units possess a button to invert the polarity of the electrodes. As an option this can also be done automatically. The electrode is thus self-cleaning, the totality of scaling that occurs during the reaction product settles to the bottom of the barrel.

GENERAL PRINCIPLE OF CHLORINE PRODUCTION

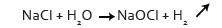

- The electrolysis units ACP system produces sodium hypochlorite (bleach) at low concentration from a salt-water solution using an electrode and an electric current.

- This current is generated by the adequately exposed solar panel. The installation is autonomous and participates in the preservation of natural resources through the promotion of renewable energy.

- • The ACP is an ideal alternative to conventional systems that use pellets (ex. HTH) involving logistical and / or financial issues for the communities. The disinfectant is produced on site and only kitchen salt (NaCl) is required.

PRACTICALLY

- Standard theoretical production capacity from 30 to 80 grams of chlorine per day, depending on the number of solar panels and sunlight.

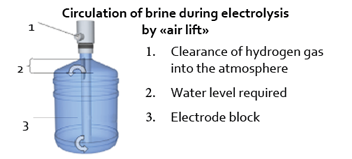

- For the electrolysis, 750 g of sodium chloride are placed in a barrel of 30 liters of water to produce a brine of a concentration of about 25 g / l.

- The current generated by electrodes that are immersed in the brine causes the formation of active chlorine in the form of sodium hypochlorite, according to the following reaction:

- During the reaction, some hydrogen gas is produced contributing to the circulation of the brine in the carboy.

Altech s.a.f.s., rue Saint-Eloi, n°95 - 4300 Waremme (Belgique) - +32 (0).19.32.47.16 - altech.safs@gmail.com